A flue fiasco

Just in time for warm weather we pulled the trigger on capping our chimneys, a project we’ve delayed for more than three years. Our house has survived two hundred seventy-something years without caps on the chimneys. When a fireplace is actively used, this is a sustainable situation. When it’s not, problems arise because critters move in.

Each spring, like clockwork, chimney swifts newly arrived from South America set up house in our living room chimney. Although there was a certain charm to hearing the plaintive chirps of the baby swifts as they were fed by their parents each evening, the knowledge that the byproducts of those feedings were accumulating above our damper was a bit off-putting.

In addition, I’d noticed a squirrel had taken a keen interest in our middle chimney, often settling atop it for long sunbaths in the late winter. More on that later.

A few weeks ago, I called the local chimney “experts” to work up an estimate. We decided to spring for durable copper caps to make this a once-and-never-again project. To sweeten the deal, we also elected to reline one of the chimneys so that we could use the living room fireplace. Although our house has 8 fireplaces (maybe 9), due to age-related deterioration of the masonry, we can’t use any of them until they’re lined properly.

My dealings with the chimney folks did not have auspicious beginnings. The first sign of trouble was when the estimator called and couldn’t figure out which chimney was which – his field technicians hadn’t relayed that information to him, even though I made a scale drawing of the roof and suggested it might be helpful for them to take it back to the office.

Later, the estimator called again to deliver the news that the liner “won’t fit” in our chimney flue. Since this was the first mention of any difficulty despite an hours-long site visit a few days earlier, I was miffed, and asked for some time to think things through. The next morning, with no interim conversations, an estimate that included the lining of the chimney appeared in my inbox. Confused, I called the estimator back and was told that he had made arrangements with a chimney supplier to fabricate a custom oval liner that would fit neatly in our flue. Although the estimate total was stomach-churning, we went for it, anticipating the luxury of a crackling fire on crisp fall nights.

Meanwhile, my gut was screaming, “These guys are a joke.” Silence, gut.

Fast forward to installation day. Again, inauspicious beginnings: the lead tech commenced hauling out bag after bag of pourable cement insulation that would be used to insulate the new liner, although I had specifically requested that we use a less permanent fiberglass wrap. After a long conversation, I conceded to using the insulation in the interest of moving the job along.

An hour or so later, I heard some loud banging and raced downstairs down to find the installers attempting to indelicately snake a 30 ft. long steel liner through my brand new kitchen. I screamed “STOP!” and politely explained the idiocy of what they were about to attempt. Taking matters into my own hands, I grabbed every scrap of cardboard I could find to fashion corner protectors for my newly-installed cabinets and walls. Then I helped to carefully steer the liner to the foot of the fireplace.

Next, the techs set up scaffolding and a winch on the roof. Once they had the liner connected to the rooftop hoist, they began slowly pulling the tube up the chimney. For the first fifteen feet or so, it was like a “hotdog down a hallway”, as they say. And then, a piercing screech as metal dragged across brick. Peering up the chimney, one of the workers in the living room yelled to his colleague on the roof, “What’s the problem?!”

A pause. “It’s stuck,” came the reply.

They weren’t kidding. The liner was wedged into place and wouldn’t budge in either direction. A variety of tools started to emerge from the crew’s supply vans. At one point, I’m fairly certain I saw someone sitting in my fireplace shoving a garden hoe up the flue. It turns out that our chimney flues twist 90 degrees halfway up. Why the chimney crew hadn’t figured this out prior to installation day, I’ll never understand. I was deliriously upset at this point, and had to excuse myself to confer with my wife.

“Send them away,” she suggested. This, unfortunately, was not an option given that half the liner was still draped across our living room floor.

The lead technician retreated to the corner for a hushed phone conversation with the owner of the company and then, channeling his inner surgeon, announced that he would have to “go in”.

“Go in?” I asked.

“Yes, we’re going to cut into the chimney from the outside to free the liner.”

The one and only ground rule I had given this company from the very first phone call was that they were not allowed to touch the exterior of the chimneys…period. The brick is historic, fragile, and held together with lime mortar, which nobody knows how to use anymore.

Those of you who know me know that I maintain a fairly even keel emotionally, but I’m certain the veins in my forehead looked like a bowl of spaghetti at hearing this news. Believing that the liner was actually stuck, I conceded to the chimney breach. But when I heard the sound of the electric grinder spinning up to speed outside, I went to the fireplace and leaned on the liner with all my might. It budged, a little at first, then more freely. I raced outside, ordered the grinding to stop, and asked the crew to get the liner out of my house.

I called the owner of the company and scolded him, more politely than I should have, for completely botching the entire operation. He admitted their fault and fed me a bunch of nonsense about using this as a “teachable moment” for his staff.

“Neanderthals can’t be taught,” I thought.

I made it clear that I would not pay for anything related to the chimney lining and asked that they cap the chimneys and leave our house, post haste.

Two days later, a different pair of technicians showed up to cap the chimneys. I reminded them that I had seen a squirrel sitting atop the middle chimney and asked that they verify for certain that no squirrels were in the flue before installing that cap.

A few hours later, they finished up and insisted that it was impossible for a squirrel to get into the middle chimney.

The following morning, I looked out our bedroom window and, sure enough, a squirrel was frantically circling the new cap on the middle chimney, gnawing at its corners. I suspected that this was an adult female squirrel trying to access babies that she had nested in the chimney. Fearing that she would chew directly through our pricey new copper caps, I spent the better part of the morning racing up and down the roof in an attempt to scare her away. After awhile, it became clear that there were only two ways this was going to get resolved: either momma squirrel was going to get her babies back, or she was going to wreck shit.

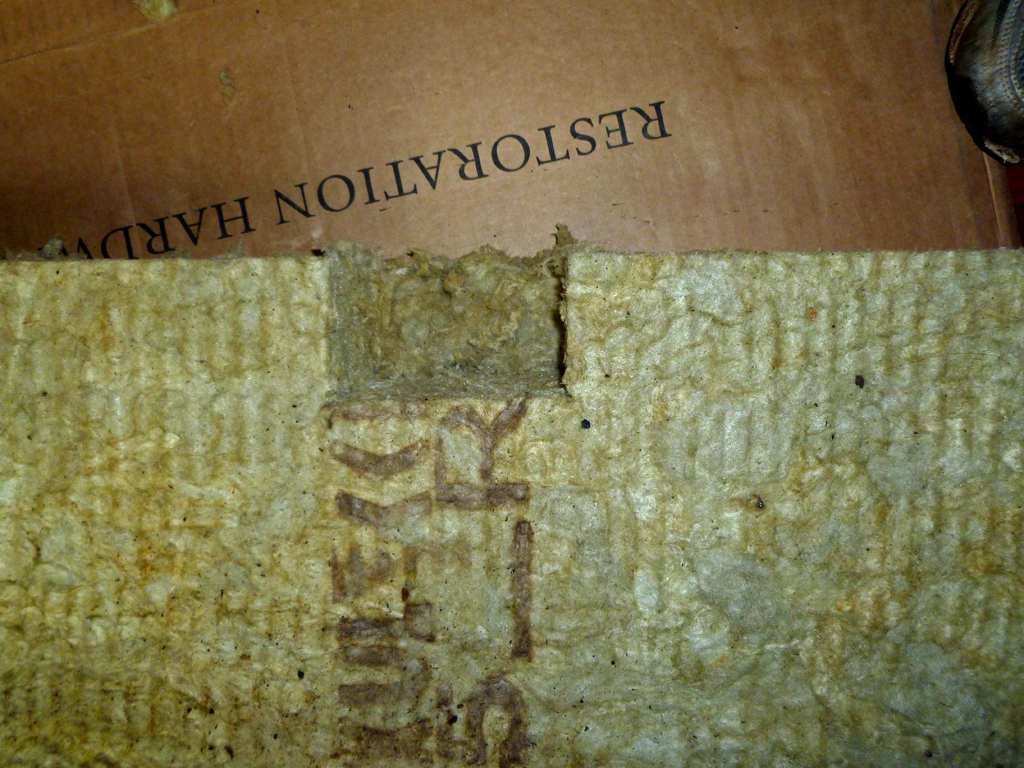

I called several wildlife control guys who were more amused than helpful when I described the situation. The only useful piece of advice I got was the suggestion that there was only one place the baby squirrels could possibly be: on top of the damper. While Weezie monitored the premises for the psychotic momma squirrel, who had temporarily retreated to plan the second wave of her attack, I set to work trying to free the damper which was weighed down by bird crap, chunks of old bricks, and (spoiler alert) a squirrel’s nest.

It took half an hour of vacuuming and persuasion, but the damper finally popped up and revealed a couple of furry baby squirrels, very unhappy to have their morning slumber interrupted. I transferred as much of the flea-ridden, ammonia-scented nest into a cardboard box as I could and carefully tucked the babies into their new accommodations. Problem (partially) solved.

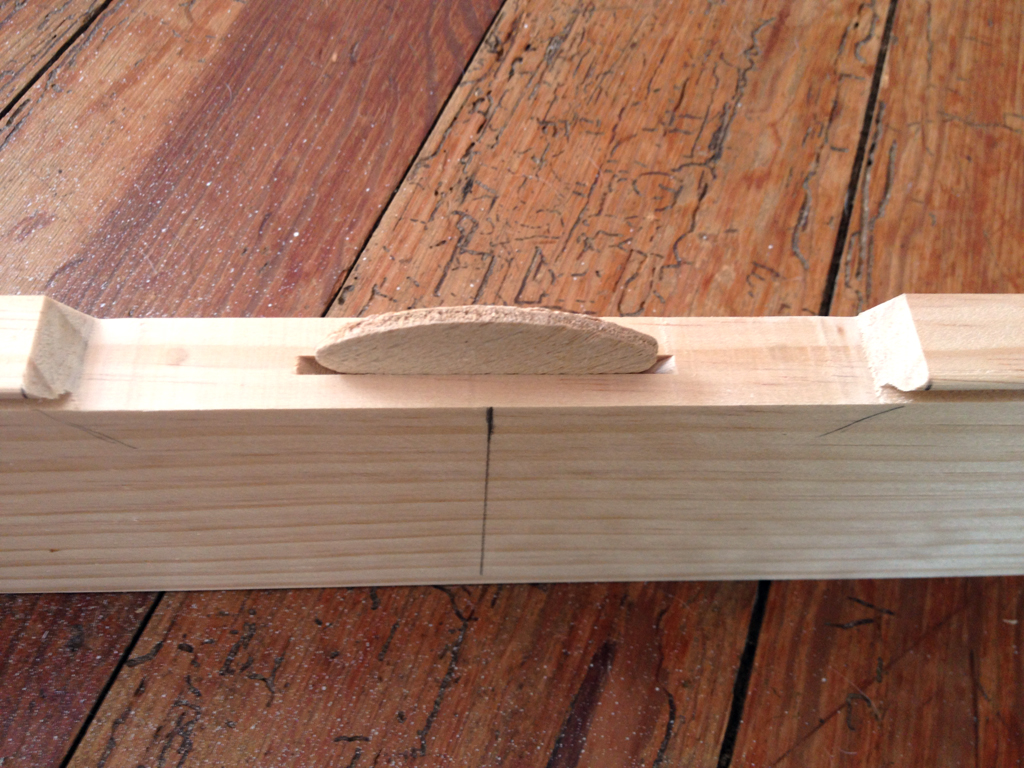

Unsure of what to do next, I turned to the world’s greatest repository of completely random information, YouTube. I quickly learned that squirrel moms will relocate their babies to backup nests if their primary home is compromised. So, I needed to get the babies to a place where their mom could find them when she returned. With some scraps of wood, I fashioned a stool that would straddle the ridge of the roof and support the box-o’-squirrels, not far from where there nest had been.

With the box perched on the roof, I sat down to wait for momma squirrel. As dusk settled in, and squirrels began scurrying across the yard towards their nightly hideouts, my target scurried down the electrical service wire to our house, scaled the side of the chimney, and planted herself on the ridge of the roof. Clearly, she could smell her babies (it would be hard not to, those are some funky critters). After a few minutes of poking around the box, she finally found the kids, tucked them into a ball in her mouth and took off to greener pastures.

I caught momma squirrel’s initial explorations on video. You can see her sniffing around the box, clearly confident that her babies are nearby, but not yet sure where to look. I apologize for the quality – I wanted to move in for a closer view, but I didn’t want to scare her away:

Thankfully, the squirrel family seems to have adapted to their new home and hasn’t returned to our rooftop. People sometimes ask me why I’m so reluctant to hire contractors to work on the house. This whole frustrating ordeal is a great example of what can happen when you mistakenly hire someone that doesn’t care about doing a good job, which seems to be frustratingly common in the trades.

To recap, after a lot of grief, we now have:

0 working fireplaces,

1 damaged chimney,

2 fewer baby squirrels in our house,

and 3 sparkly new chimney caps.

Was all the grief worth it? Absolutely not. It’s nice to have the chimneys capped for good, but next time I hire someone, my gut gets the last word.

Until then, I’ll strive to attain the level of Zen-like chill that our dog Meg has mastered: